Max Feeding:

45-1000kw.Capacity:

1.4-50tph.Application:It is used in metallurgy industry,building materials,water conservancy,mining,construction industry,etc

Application range:Widely used in metallurgy, mining, chemical, cement, construction, refractory materials and ceramics industries.

Email: jacker@cfcmining.com

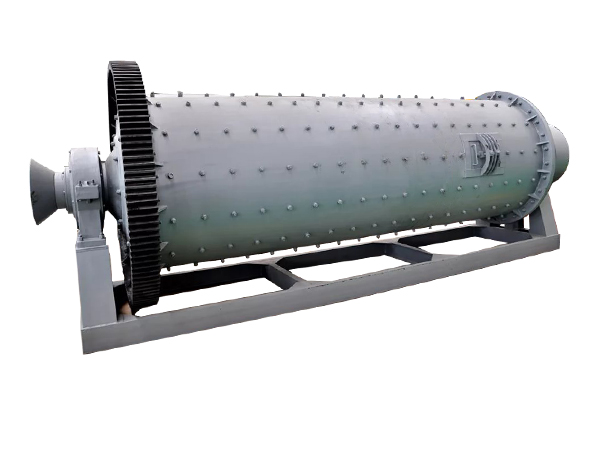

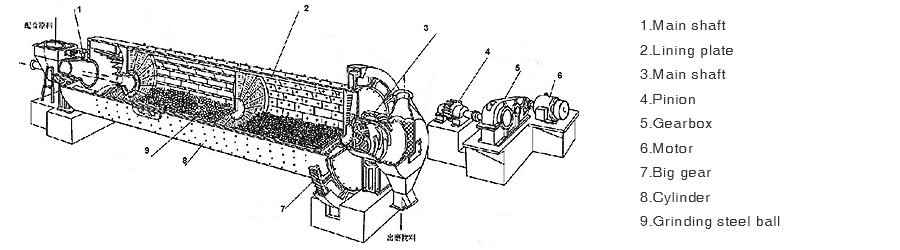

Cement mill is also called cement ball mill, which is mainly used for grinding cement clinker in the cement production process. It is one of the important cement equipment.

The output of cement mill is 21~155 t/h, and the specific surface area of cement is 3300~3800 cm ² /g. Cement mill has the advantages of small occupied area, stable running, convenient operation and other advantages, so as to achieve the high yield and high fineness, which has provided a strong guarantee for the production of high quality cement. According to the different needs of cement, it can adopt the edge transmission or center transmission, which has flexible configuration.

| Model (m) |

Capacity (t/h) |

Mill Form |

Transmission Form |

Power (kw) |

Reducer | Weight (t) |

Remarks | |

| Model | Ratio | |||||||

| 2.2×7m | 8-9 | Open Flow | Edge | 380 | ZD70 | 5 | 54 | / |

| 2.2×7.5m | 10-11 | Open Flow | Edge | 380 | ZD70 | 5 | 63 | / |

| 2.2×8m | 10-12 | Open Flow | Edge | 380 | ZD70 | 5 | 65 | / |

| 2.2×9.5m | 14-16 | Open Flow | Edge | 475 | ZD70 | 5 | 70 | / |

| 2.4×10m | 19-19 | Open Flow | Edge | 630 | JR75 | 5.64 | 94.5 | Without motor |

| 2.4×11m | 19-21 | Open Flow | Edge | 630 | RZD80 | 6.3 | 99.2 | Without motor |

| 2.4×13m | 21-23 | Open Flow | Edge | 800 | MBY710 | 7.1 | 115.2 | Without motor |

| 2.6×13m | 28-32 | Open Flow | Edge | 1000 | MBY800 | 7.1 | 148 | / |

| 2.6×13m | 28-32 | Open Flow | Edge | 1000 | MFY100 | 19.5 | 101.73 | / |

| 3×12m | 32-35 | Open Flow | Edge | 1250 | MBY900 | 7.1 | 168.6 | / |

Relate Products

Relate Products

Others Products

Others Products

About CFTC PE jaw crusher Price in India: Sold to the region: India Type: Jaw Crusher(PE250*400,PE400*600,PE600*900,PE250*1000) Application: Construction, Mine

In the procedure of purchasing small stone jaw crusher, the majority of consumers pay more attention to how much is one, and there are many buyers on the market. Today we will introduce the price of small-sized E-type stone crusher as follows, hoping to h

Cone crusher has become a wide range of crushing equipment. Its crushing ratio is large, its efficiency is high, its energy consumption is low, and its uniform particle size makes it suitable for crushing hard or medium-hard ore..