Max Feeding:

1200×1500Capacity:

400-800 tphApplication:

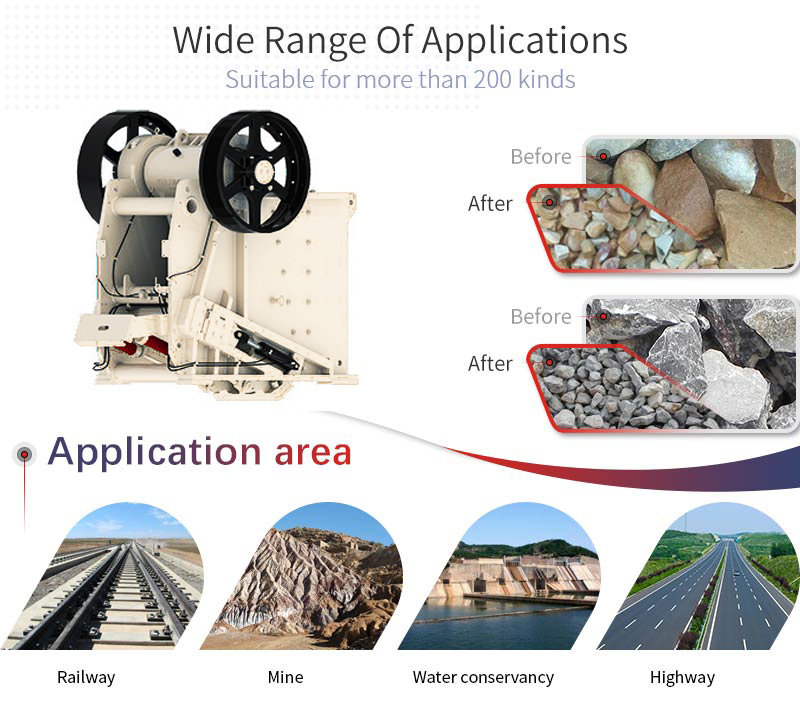

Application range:Widely used in metallurgy, mining, chemical, cement, construction, refractory materials and ceramics industries.

Email: jacker@cfcmining.com

The Concrete Telsmith Jaw Stone Crusher can reach the crushing ratio of 4-6 and the shape of final product is even. They are widely applied to crush high hardness, MID hardness and soft rocks and ores such as slags, construction materials, marble, etc.

By the principle of mutual extrusion of materials, Telsmith Jaw Stone Crusher is used for the coarse crushing. Various ore with compression resistance no higher than 350MPa can be processing to medium-grained. Our design and production are of high position both at home and abroad. One of our main products, Jaw Crusher is designed by our engineers with large reduction ratio, even granularity, simple structure, reliable operation, convenient maintenance, low cost, This series of jaw crusher can reach the crushing ratio of 4-6 and the shape of final product is even. They are widely applied to crush high hardness, MID hardness and soft rocks and ores such as slags, construction materials, marble, etc.

Concrete Telsmith Jaw Stone Crusher Working Principle:

The motor transmits power through belt, and drives the movable jaw do periodic motion to the fixed jaw surrounding the eccentric shaft. When the movable jaw goes up, closing to the fixed jaw plate, the stuff will be crushed, twisted and grinded in this process. When the movable jaw of jaw crusher moves away from fixed jaw plate by the pulling of rod and spring, the products after crushing will be discharged from the outlet of Jaw crusher with the function of gravity. With the continuous rotation of the motor, movable jaw crushes and discharges periodically for mass production.

| Type | Feed port size (mm) |

Max Feeding (mm) |

Capacity (t/h) |

Power (kw) |

Weight (t) |

Shape(mm) |

| PE-150×250 | 150×250 | 125 | 1-3 | 4P 5.5 | 0.8 | 720×660×850 |

| PE-200×300 | 200×300 | 180 | 2-6 | 4P 7.5 | 1.2 | 910×750×990 |

| PE-200×350 | 200×350 | 180 | 3-10 | 4P 11 | 1.5 | 1000×870×990 |

| PE-250×400 | 250×400 | 210 | 5-21 | 6P 15 | 2.8 | 1300×1090×1270 |

| PE-400×600 | 400×600 | 340 | 16-64 | 6P 30 | 7 | 1730×1730×1630 |

| PE-500×750 | 500×750 | 425 | 40-110 | 6P 55 | 12 | 1980×2080×1870 |

| PE-600×750 | 600×750 | 500 | 80-240 | 6P 55 | 15.8 | 2070×2000×1920 |

| PE-600×900 | 600×900 | 500 | 50-160 | 6P 55 | 17 | 2190×2206×2300 |

| PE-750×1060 | 750×1060 | 630 | 110-320 | 8P 110 | 29 | 2660×2430×2800 |

| PE-800×1060 | 800×1060 | 640 | 130-330 | 8P 110 | 29.8 | 2710×2430×2800 |

| PE-830×1060 | 830×1060 | 650 | 150-336 | 8P 110 | 30.7 | 2740×2430×2800 |

| PE-870×1060 | 870×1060 | 660 | 190-336 | 8P 110 | 31.5 | 2810×2430×2800 |

| PE-900×1060 | 900×1060 | 685 | 230-390 | 8P 110 | 33 | 2870×2420×2940 |

| PE-900×1200 | 900×1200 | 750 | 220-380 | 8P 110 | 52 | 3380×2870×3330 |

| PE-1000×1200 | 1000×1200 | 850 | 315-500 | 8P 110 | 55 | 3480×2876×3330 |

| PE-1200×1500 | 1200×1500 | 1020 | 400-800 | 6P 160-220 | 100.9 | 4200×3300×3500 |

| PE-1500×1800 | 1500×1800 | 1200 | 500-1000 | 8P 280-355 | 139 | 5160×3660×4248 |

| PEX-150×750 | 150×750 | 120 | 8-25 | 4P 15 | 3.8 | 1200×1530×1060 |

| PEX-250×750 | 250×750 | 210 | 13-35 | 6P 22 | 5.5 | 1380×1750×1540 |

| PEX-250×1000 | 250×1000 | 210 | 16-52 | 6P 30 | 7 | 1560×1950×1390 |

| PEX-250×1200 | 250×1200 | 210 | 20-61 | 6P 37 | 9.7 | 2140×1660×1500 |

| PEX-300×1300 | 300×1300 | 250 | 16-105 | 6P 55 | 15.6 | 2720×1950×1600 |

Relate Products

Relate Products

Others Products

Others Products

Portable Diesel Engine Stone Crusher Jaw Crusher are primarily used for crushing various kinds of stones and lump materials into medium-grained gravel.

The European version of the CJ jaw crusher, also known as the CJ European version of the jaw crusher.

The normal work of the jaw crusher is not only limited to reasonable operation and usual repair and test, minor repair, medium repair and overhaul, we should also carry out maintenance on a budget.