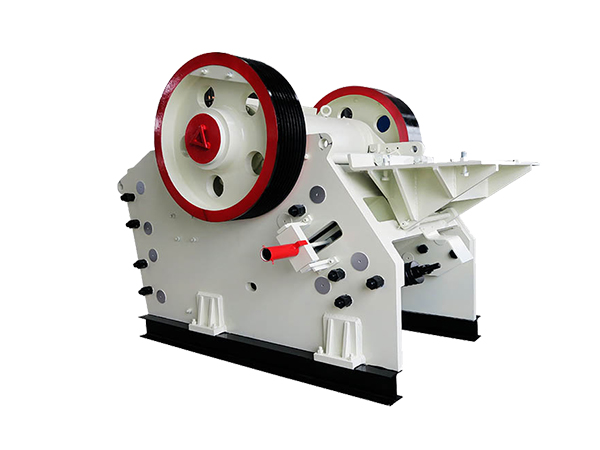

Max Feeding:

430-1360mmCapacity:

50-1500tphApplication:iron ore, manganese ore, gold ore, pebble, granite, limestone, river stone, aluminum ore, etc..

Application range:Widely used in metallurgy, mining, chemical, cement, construction, refractory materials and ceramics industries.

Email: jacker@cfcmining.com

JC Jaw Crusher has small space, larger crushing ratio and more stable operation. It has more advantages in transportation installation and maintenance adjustment. Particularly suitable for use in fixed crushing lines and mobile crushing plants.

| Model | Feed Opening (mm) |

Max. Feed Size (mm) |

CSS(mm) / Throughput Hard/Soft rock Capacity(TPH) | ||||||||||||||

| 40 | 50 | 60 | 70 | 80 | 90 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 275 | 300 | |||

| JC80 | 800×510 | 430 | 50 | 55 | 80 | 90 | 110 | 120 | 135 | 170 | 200 | 240 | |||||

| 70 | 85 | 100 | 125 | 145 | 170 | 185 | 240 | 280 | 330 | ||||||||

| JC90 | 910×630 | 530 | 90 | 105 | 115 | 135 | 150 | 170 | 200 | 230 | 275 | ||||||

| 130 | 140 | 165 | 185 | 200 | 240 | 270 | 300 | 345 | |||||||||

| JC100 | 1000×760 | 640 | 120 | 140 | 155 | 175 | 210 | 250 | 300 | 340 | |||||||

| 170 | 195 | 215 | 255 | 300 | 350 | 420 | 480 | ||||||||||

| JC110 | 1100×850 | 720 | 180 | 200 | 220 | 245 | 300 | 350 | 400 | 460 | |||||||

| 240 | 265 | 295 | 320 | 385 | 455 | 520 | 590 | ||||||||||

| JC125 | 1250×950 | 810 | 270 | 325 | 385 | 445 | 500 | 560 | 620 | ||||||||

| 360 | 430 | 505 | 580 | 650 | 725 | 800 | |||||||||||

| JC140 | 1400×1070 | 910 | 360 | 425 | 490 | 555 | 625 | 690 | 725 | ||||||||

| 470 | 555 | 640 | 725 | 815 | 900 | 985 | |||||||||||

| JC160 | 1600×1200 | 1020 | 490 | 560 | 635 | 710 | 780 | 855 | 930 | ||||||||

| 640 | 730 | 825 | 920 | 1010 | 1105 | 1200 | |||||||||||

| JC210 | 2100×1600 | 1360 | 800 | 900 | 1000 | 1100 | 1200 | 1300 | |||||||||

| 880 | 1005 | 1125 | 1225 | 1375 | 1500 | ||||||||||||

Relate Products

Relate Products

Others Products

Others Products

The Concrete Telsmith Jaw Stone Crusher greatly improves the crushing efficiency and crushing quality of the processing plant, bringing considerable benefits to customers. What is the price new model of Concrete Telsmith Jaw Stone Crusher in my country? W

The role of different parts together ensures the safe production process of the equipment. The lining board is one of the machine parts. Here is the role of the lining board.

PE jaw crusher is the main equipment in the coarse crushing stage of industrial gravel process. It is mainly composed of moving jaws, fixed jaws, spindles, connecting rods, body parts, etc., in order to assist customers to better use this equipment. The f