Max Feeding:

≤ 35 mm.Capacity:

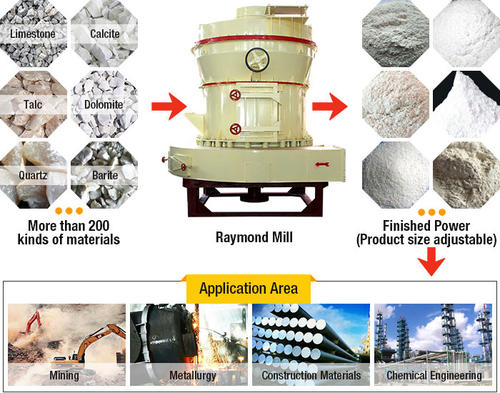

0.2 - 60t/hApplication:Barite, calcite, potassium feldspar, talc, marble, limestone, dolomite, fluorite, lime, activated clay, activated carbon, bentonite, kaolin, cement, phosphate rock, gypsum, glass, insulation materials, etc..

Application range:Widely used in metallurgy, mining, chemical, cement, construction, refractory materials and ceramics industries.

Email: jacker@cfcmining.com

Raymond mills can be used for the high-fine power processing in minerals, chemicals, construction, and other industries.

Raymond mills can be used to process more than 280 non-flammable and explosive materials with a Mohs hardness of less than 9.3 and a humidity of less than 6%, such as barite, calcite, and potassium feldspar, talc, marble, limestone, dolomite, fluorite, lime, activated clay, activated carbon, bentonite, kaolin, cement, phosphate rock, gypsum, glass, insulation, etc.

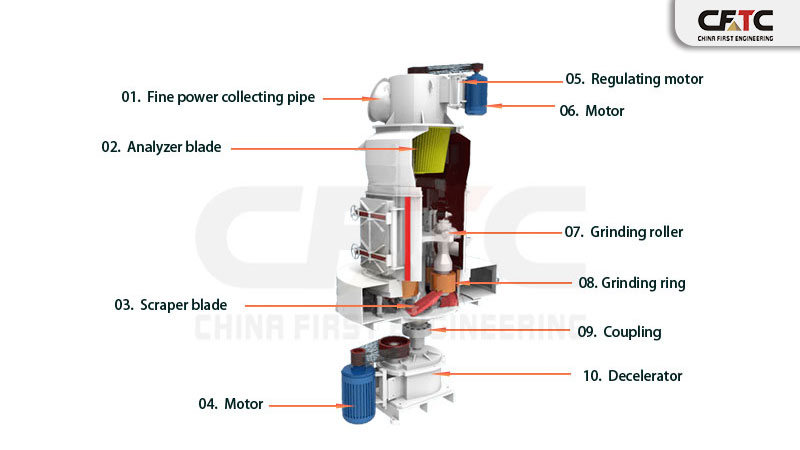

After the material is pulverized to the required particle size, the material is sent to the storage hopper by the hoist, and then the material is uniformly and continuously fed into the main grinding chamber of the Raymond mill by the vibrating feeder. The centrifugal roller acts outward due to the centrifugal force during the rotation. Swinging, pressing the grinding ring, the blade shovels the material and sends it between the grinding roller and the grinding ring, which is crushed by the rolling of the grinding roller. The fine powder after grinding of the material is brought into the analysis machine for sorting with the circulating wind of the blower, and the finely coarse material falls back to the regrind, and the qualified fine powder enters the finished cyclone powder collector with the airflow, and is discharged through the powder discharging tube. It is the finished product.

| type | 3R2615 | 3R2715 | 3R3016 | 4R3216 | 5R4121 | 6R4427 | |

| grinding rolls(Number) | Number | 3 | 3 | 3 | 4 | 5 | 6 |

| diameter(mm) | 260 | 270 | 300 | 320 | 410 | 440 | |

| height(mm) | 150 | 150 | 160 | 160 | 210 | 270 | |

| Grinding ring | inside diameter(mm) | 780 | 830 | 880 | 970 | 1280 | 1600 |

| height(mm) | 150 | 150 | 160 | 160 | 210 | 270 | |

| Input size(mm) | <15 | <15 | <20 | <25 | <30 | <35 | |

| Finished product size(mm) | 0.044-0.165 | 0.044-0.165 | 0.044-0.165 | 0.044-0.165 | 0.95-0.033 | 1.9-0.045 | |

| power(kw) | 18.5 | 22 | 30 | 37 | 75 | 132 | |

| capacity(t/h) | 0.2-2 | 0.8-3.5 | 1-5.2 | 5.2-12.5 | 12.2-20 | 20-60 | |

Relate Products

Relate Products

Others Products

Others Products

The ball mill is the key equipment for crushing the material after it has been crushed. This type of grinding machine is equipped with a certain number of steel balls as grinding media in its cylinder.