Max Feeding:

0-930mmCapacity:

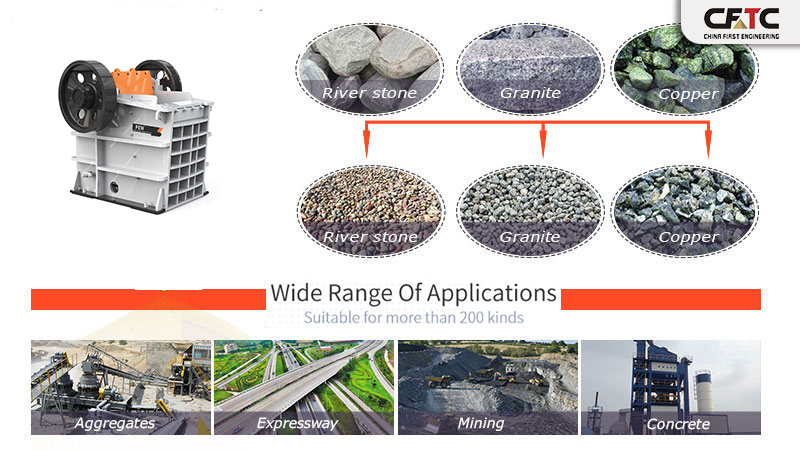

12-650TPHApplication:Granite, marble, basalt, limestone, quartz, pebble, copper ore, iron ore

Application range:Widely used in metallurgy, mining, chemical, cement, construction, refractory materials and ceramics industries.

Email: jacker@cfcmining.com

PEW Jaw Crusher is mainly used for medium-size crushing of various ores and bulk materials, and is widely used in mining, smelting, building materials, roads, railways, water conservancy and chemical industries.

PEW series jaw crusher different types of crushes price for sale is typically used as primary crusher or the first step in the process of reducing rock. They typically crush using compression. It is widely used in Mining, metallurgy, construction, highway, railroad, and water conservancy, etc.. It can process Iron ore, copper ore, gold ore, manganese ore, river stone, gravel, granite, basalt, minerals, quartz, diabase, etc.

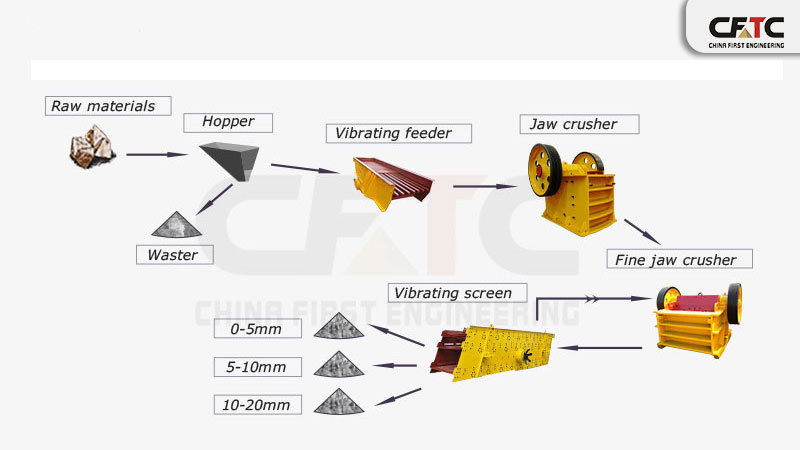

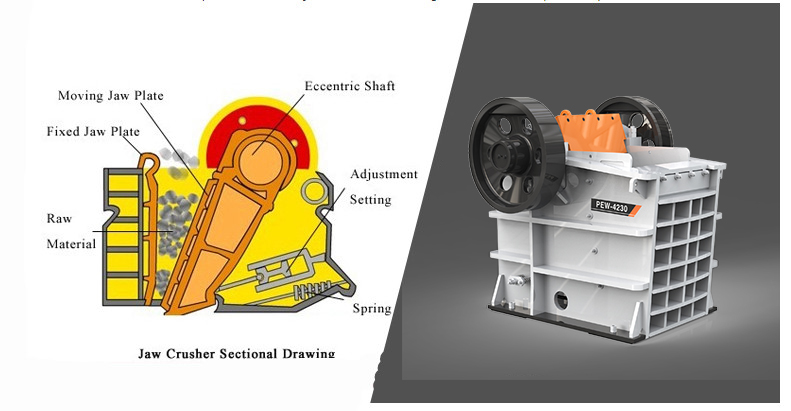

PEW series jaw crusher working principle:

The PEW series jaw crusher crushing method of is dynamic squeeze. The working principle is: the electromotor drives the belt and pulley to make the movable jaw move back and forth, up and down through the eccentric shaft. The raw material is squashed or splitt when movable jaw plate moves towards fixed jaw together with movable jaw. When movable jaw and movable jaw plate turn back by eccentric shaft and spring, the raw material, which is squashed or split before discharges from the bottom outlet under jaw plate. The bulk-production comes true while electromotor rotates continuously and the movable jaw crushes and discharges the raw material periodically.

| Model | Feed opening (mm) | Maximum feeding size (mm) | Range of discharge opening (mm) | Capacity (t/h) | Speed (r/min) | Power (kw) | Overall dimension (mm) |

| PEW250×1000 | 250×1000 | 220 | 20-40 | 15-50 | 330 | 30 | 1400×1850×1310 |

| PEW250×1200 | 250×1200 | 220 | 20-40 | 20-50 | 330 | 37 | 1400×2050×1310 |

| PEW400×600 | 400×600 | 350 | 35-85 | 15-70 | 250 | 37 | 1920×1460×1840 |

| PEW760 | 760×1100 | 640 | 75-200 | 150-350 | 270 | 110 | 2600×2500×2200 |

| PEW860 | 860×1100 | 720 | 100-225 | 200-500 | 240 | 132 | 3300×2320×3120 |

| PEW1100 | 1100×1200 | 930 | 150-275 | 300-650 | 210 | 185 | 4140×2660×3560 |

Relate Products

Relate Products

Others Products

Others Products

The jaw plate is the most important accessory in the jaw crusher and the most vulnerable part, so it often needs to be replaced.

PE jaw crusher is the main equipment in the coarse crushing stage of industrial gravel process. It is mainly composed of moving jaws, fixed jaws, spindles, connecting rods, body parts, etc., in order to assist customers to better use this equipment. The f

The c160 jaw crusher greatly improves the crushing efficiency and crushing quality of the processing plant, bringing considerable benefits to customers. What is the price new model of c160 jaw crusher in my country? What is the effect? The CFTC is briefly