Max Feeding:

≤340mm.Capacity:

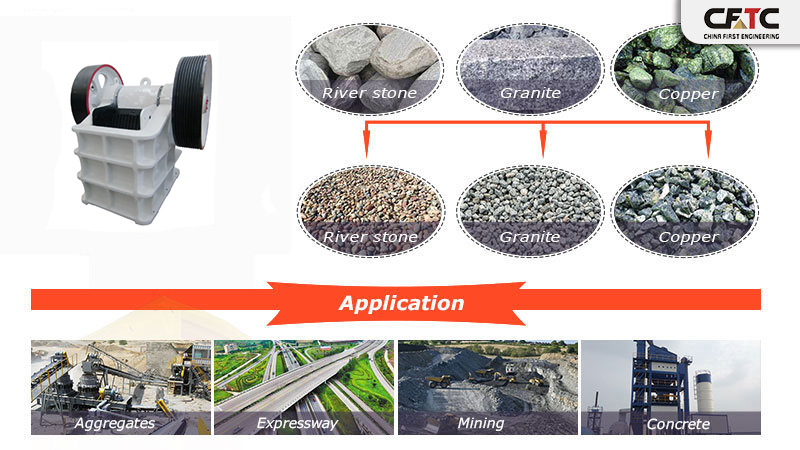

16-64 tphApplication:granite, marble, basalt, limestone, quartz, cobble, iron ore, copper ore, and some other mineral & rocks.

Application range:Widely used in metallurgy, mining, chemical, cement, construction, refractory materials and ceramics industries.

Email: jacker@cfcmining.com

Stone Jaw Crusher pe 400 x 600 is the traditional product in crushing and beneficiation plants, it is suitable for crushing a variety of soft and hard ores and rocks.

Stone Jaw Crusher Pe 400 x 600 is used to crush materials which hardness coarse and medium, with comprehensive resistance less than 320MPA.Such as granite, marble, basalt, limestone, quartz, cobble, iron ore, copper ore, and some other mineral & rocks.The Jaw Crusher Pe 400 x 600 are widely used in various materials processing of mining and construction industries, road and railway etc.

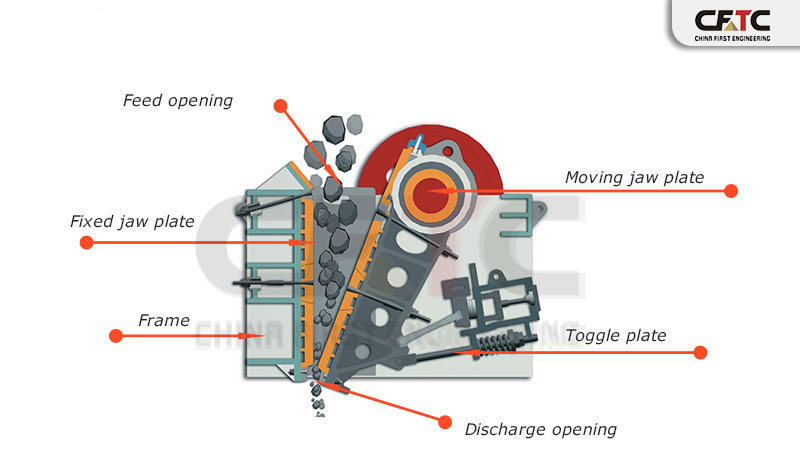

This machine is of complex swing type, mainly composed of body, movable jaw, eccentric shaft, jaw plate, adjusting device and so on. The body with a steel plate welded together, it is a machine frame, supporting all the movement parts and material crushing during extrusion, movable jaw, eccentric shaft and move jaw plate are the machine movement of parts, The movable jaw is equipped with a high manganese cast jaw plate and it can be turned back after wear to extended service life, The rear wall panel of the machine is fitted with bracket and adjusting device, by elastic handle (example: PEX150 x 750, PE400 type) and elastic plate(example: PEX250 * 1000, PE250 type) to adjust the size of the discharge port.

| Type | Feed port size (mm) |

Max Feeding (mm) |

Capacity (t/h) |

Power (kw) |

Weight (t) |

Shape(mm) |

| PE-150×250 | 150×250 | 125 | 1-3 | 4P 5.5 | 0.8 | 720×660×850 |

| PE-200×300 | 200×300 | 180 | 2-6 | 4P 7.5 | 1.2 | 910×750×990 |

| PE-200×350 | 200×350 | 180 | 3-10 | 4P 11 | 1.5 | 1000×870×990 |

| PE-250×400 | 250×400 | 210 | 5-21 | 6P 15 | 2.8 | 1300×1090×1270 |

| PE-400×600 | 400×600 | 340 | 16-64 | 6P 30 | 7 | 1730×1730×1630 |

| PE-500×750 | 500×750 | 425 | 40-110 | 6P 55 | 12 | 1980×2080×1870 |

| PE-600×750 | 600×750 | 500 | 80-240 | 6P 55 | 15.8 | 2070×2000×1920 |

| PE-600×900 | 600×900 | 500 | 50-160 | 6P 55 | 17 | 2190×2206×2300 |

| PE-750×1060 | 750×1060 | 630 | 110-320 | 8P 110 | 29 | 2660×2430×2800 |

| PE-800×1060 | 800×1060 | 640 | 130-330 | 8P 110 | 29.8 | 2710×2430×2800 |

| PE-830×1060 | 830×1060 | 650 | 150-336 | 8P 110 | 30.7 | 2740×2430×2800 |

| PE-870×1060 | 870×1060 | 660 | 190-336 | 8P 110 | 31.5 | 2810×2430×2800 |

| PE-900×1060 | 900×1060 | 685 | 230-390 | 8P 110 | 33 | 2870×2420×2940 |

| PE-900×1200 | 900×1200 | 750 | 220-380 | 8P 110 | 52 | 3380×2870×3330 |

| PE-1000×1200 | 1000×1200 | 850 | 315-500 | 8P 110 | 55 | 3480×2876×3330 |

| PE-1200×1500 | 1200×1500 | 1020 | 400-800 | 6P 160-220 | 100.9 | 4200×3300×3500 |

| PE-1500×1800 | 1500×1800 | 1200 | 500-1000 | 8P 280-355 | 139 | 5160×3660×4248 |

| PEX-150×750 | 150×750 | 120 | 8-25 | 4P 15 | 3.8 | 1200×1530×1060 |

| PEX-250×750 | 250×750 | 210 | 13-35 | 6P 22 | 5.5 | 1380×1750×1540 |

| PEX-250×1000 | 250×1000 | 210 | 16-52 | 6P 30 | 7 | 1560×1950×1390 |

| PEX-250×1200 | 250×1200 | 210 | 20-61 | 6P 37 | 9.7 | 2140×1660×1500 |

| PEX-300×1300 | 300×1300 | 250 | 16-105 | 6P 55 | 15.6 | 2720×1950×1600 |

Relate Products

Relate Products

Others Products

Others Products

Crushing mechanism of jaw crusher: relying on the crushing movement of the movable jaw relative to the fixed jaw to crush the material, so the wear of the jaw plate during use is quite serious.

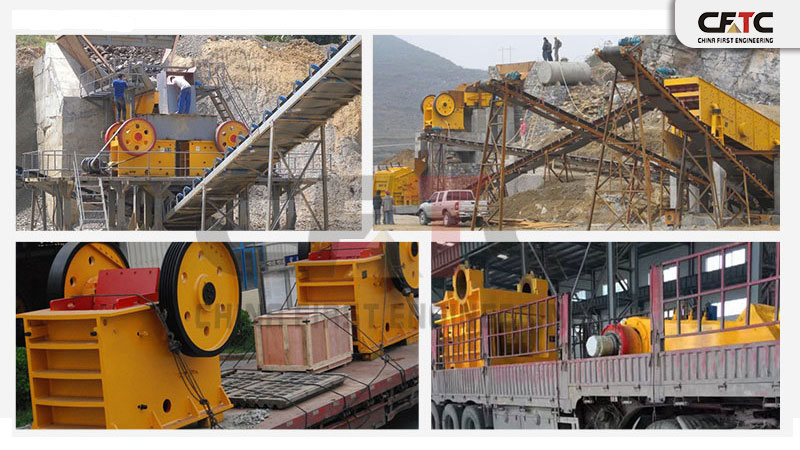

At present, the sales volume of jaw crusher produced by CFTC is very considerable at home and abroad.

What are the outstanding characteristics of river pebble crushing and sand making equipment?