Max Feeding:

≤950mmCapacity:

50-910t/hApplication:River stone, granite, basalt, iron ore, limestone, quartz, diabase, construction waste, iron ore, gold, etc.

Application range:Widely used in metallurgy, mining, chemical, cement, construction, refractory materials and ceramics industries.

Email: jacker@cfcmining.com

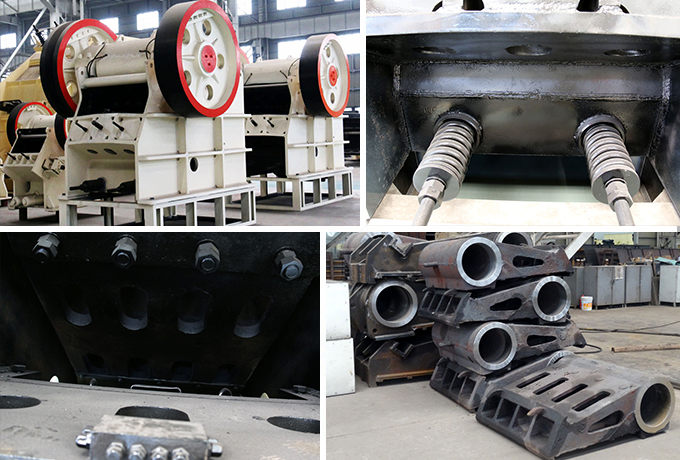

The HD jaw crusher is characterized by the close cooperation of the optimized design of the crushing cavity type and the motion parameters, which not only greatly improves the machine capacity and product quality, but also expands the application range of

| Type | Feed port size (mm) | Max Feeding(mm) | Capacity(t/h) | Power(kw) | Shape (L×W×C)(mm) |

| HD72(57) | 460×720 | 425 | 50-120 | 6P 55 | 1566×1965×1630 |

| HD86(69) | 580×860 | 500 | 60-210 | 8P 75 | 1722×1943×1810 |

| HD98(751) | 680×980 | 630 | 110-330 | 8P 110 | 1960×2470×2180 |

| HD110(912) | 850×1100 | 750 | 230-450 | 6P 132 | 2381×2775×2500 |

| HD125 | 950×1250 | 900 | 280-750 | 8P 160 | 2600×3320×3120 |

Relate Products

Relate Products

Others Products

Others Products

The jaw crusher and the cone crusher are both crushed materials. Why are the prices different? What's the difference?

The jaw plate is the most important accessory in the jaw crusher and the most vulnerable part, so it often needs to be replaced.

The jaw crusher made by our company has been the best seller on the market.