Max Feeding:

≤340mm.Capacity:

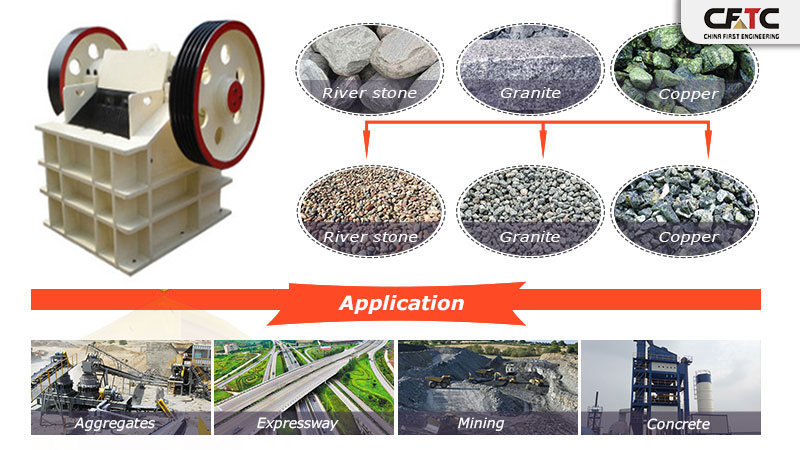

5-21TPH.Application:Limestone, quartz, iron ore, bluestone, river pebble, granite, etc.

Application range:Widely used in metallurgy, mining, chemical, cement, construction, refractory materials and ceramics industries.

Email: jacker@cfcmining.com

By the principle of mutual extrusion of materials, jaw crusher is used for the coarse crushing. Various ore with compression resistance no higher than 350MPa can be processing to medium-grained.

As a classic primary crusher with stable performances, Jaw Crusher pe 250 x 400 is widely used to crush metallic and non-metallic ores as well as building aggregates or to make artificial sand.

Product Features: Inheritance of century-old classics, simple structure, stable working performances.

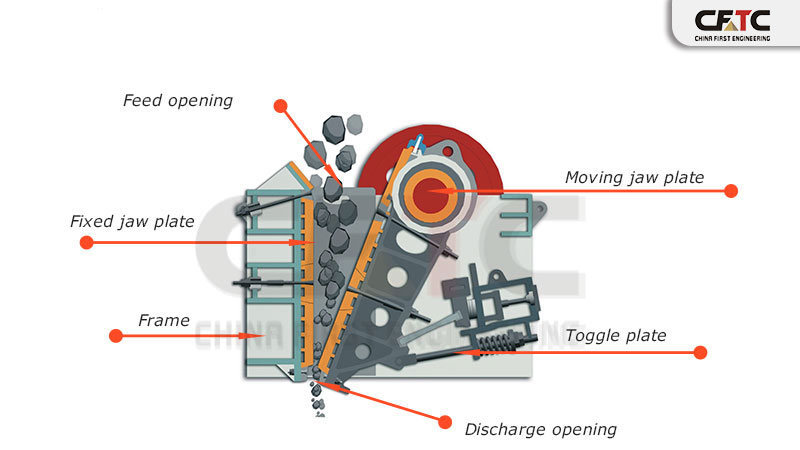

Working principle of jaw crusher pe 250 x 400:

The electrical motor transmits power to the eccentric shaft through v-belt and belt pulley. Then the exciting force generated by the eccentric shaft will make the movable jaw move upwards and downwards. This movement would trigger the toggle plate to push the movable jaw forwards and backwards. When the movable jaw moves forth towards the fixed jaw, materials in the crushing cavity will be squashed or chopped. And then the movable jaw travels back, the chopped or squashed materials which meet the requirement will be discharged from the outlet. Since the motor keeps working. The crusher will crush and discharge periodically to achieve mass production.

| Type | Input size(mm) | Adjustment range(mm) | capacity(t/h) | speed(r/min) | power(kw) | weight(t) | Shape size (mm) |

| PE-150×250 | 150×250 | 10-40 | 1-3 | 250 | 4P 5.5 | 0.8 | 720×660×850 |

| PE-200×300 | 200×300 | 15-50 | 2-6 | 260 | 4P 7.5 | 1.2 | 910×750×990 |

| PE-200×350 | 200×350 | 18-70 | 3-10 | 260 | 4P 11 | 1.5 | 1000×870×990 |

| PE-250×400 | 250×400 | 20-60 | 5-21 | 300 | 6P 15 | 2.8 | 1300×1090×1270 |

| PE-400×600 | 400×600 | 40-100 | 16-60 | 275 | 6P 30 | 7 | 1730×1730×1630 |

| PE-500×750 | 500×750 | 50-100 | 40-110 | 275 | 6P 55 | 12 | 1980×2080×1870 |

| PE-600×750 | 600×750 | 150-200 | 80-240 | 275 | 6P 55 | 15.8 | 2070×2000×1920 |

| PE-600×900 | 600×900 | 65-160 | 50-160 | 250 | 6P 55 | 17 | 2190×2206×2300 |

| PE-750×1060 | 750×1060 | 80-140 | 110-320 | 250 | 8P 110 | 29 | 2660×2430×2800 |

| PE-800×1060 | 800×1060 | 130-190 | 130-330 | 250 | 8P 110 | 29.8 | 2710×2430×2800 |

| PE-830×1060 | 830×1060 | 160-220 | 150-336 | 250 | 8P 110 | 30.7 | 2740×2430×2800 |

| PE-870×1060 | 870×1060 | 200-260 | 190-336 | 250 | 8P 110 | 31.5 | 2810×2430×2800 |

| PE-900×1060 | 900×1060 | 230-290 | 230-390 | 250 | 8P 110 | 33 | 2870×2420×2940 |

| PE-900×1200 | 900×1200 | 95-165 | 220-380 | 200 | 8P 110 | 52 | 3380×2870×3330 |

| PE-1000×1200 | 1000×1200 | 195-265 | 315-500 | 200 | 8P 110 | 55 | 3480×2876×3330 |

| PE-1200×1500 | 1200×1500 | 150-350 | 400-800 | 180 | 6P 160-220 | 100.9 | 4200×3300×3500 |

| PE-1500×1800 | 1500×1800 | 220-350 | 500-1000 | 180 | 8P 280-355 | 139 | 5160×3660×4248 |

| PEX-150×750 | 150×750 | 18-48 | 8-25 | 320 | 4P 15 | 3.8 | 1200×1530×1060 |

| PEX-250×750 | 250×750 | 25-60 | 13-35 | 330 | 6P 22 | 5.5 | 1380×1750×1540 |

| PEX-250×1000 | 250×1000 | 25-60 | 16-52 | 330 | 6P 30 | 7 | 1560×1950×1390 |

| PEX-250×1200 | 250×1200 | 25-60 | 20-61 | 330 | 6P 37 | 9.7 | 2140×1660×1500 |

| PEX-300×1300 | 300×1300 | 20-90 | 16-105 | 300 | 6P 55 | 15.6 | 2720×1950×1600 |

Relate Products

Relate Products

Others Products

Others Products

What are the outstanding characteristics of river pebble crushing and sand making equipment?

The jaw crusher made by our company has been the best seller on the market.

Jaw crusher is the most basic crushing equipment of the mine crushing production line. It roughly crushes the raw stone from the quarry. It is the first key to crush the stone into the production line.