Max Feeding:

<125mmCapacity:

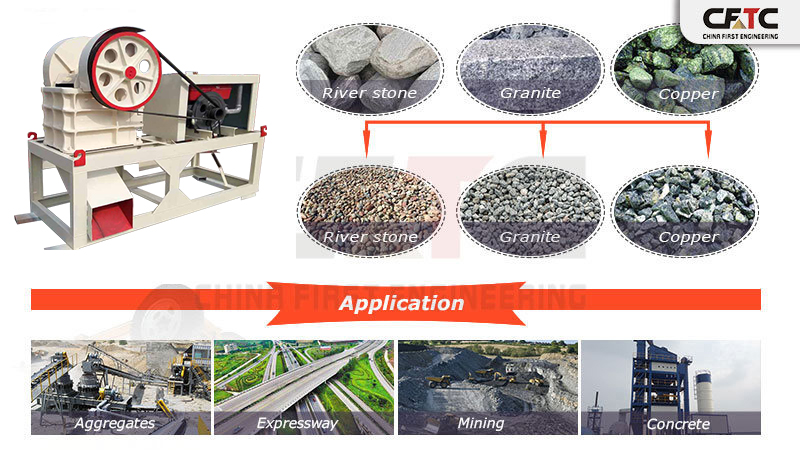

1-3 tphApplication:Granite, Basalt, Marble, ect, Quarry, granite, aggregate, limestone...

Application range:Widely used in metallurgy, mining, chemical, cement, construction, refractory materials and ceramics industries.

Email: jacker@cfcmining.com

The Jaw Crusher PE 150x250 is characterized by large crushing ratio, uniform product size, simple structure, reliable work, simple maintenance and economical operation cost.

Jaw crusher pe 150 x 250 can reach the crushing ratio of 4-6 and the shape of final product is even.Mini Jaw Crushers are widely applied to crush high hardness, mid hardness and soft rocks and ores such as slag, construction materials, marble, etc. The pressure resistance strength is under 200Mpa, that is, suitable for primary crush. Jaw crushers can be used in mining, metallurgical industry, construction, road and railway building, water conservancy, chemistry, etc.

jaw crusher pe 150 x 250 working principle:

The working principle of jaw crusher is very simple. The whole crushing process rely on the relative motion of the two jaw plates.The materials between the two plates would be crushed into small elements. While the plates move against each other, the materials would be crushed and while plates move away from each other, the broken materials which are smaller enough would drop through the discharging opening. And due to the simple structure, jaw crusher is easy to maintain and repair. These features promote its popularity to a great extant.

| Type | Feed port size (mm) |

Max Feeding (mm) |

Capacity (t/h) |

Power (kw) |

Weight (t) |

Shape(mm) |

| PE-150×250 | 150×250 | 125 | 1-3 | 4P 5.5 | 0.8 | 720×660×850 |

| PE-200×300 | 200×300 | 180 | 2-6 | 4P 7.5 | 1.2 | 910×750×990 |

| PE-200×350 | 200×350 | 180 | 3-10 | 4P 11 | 1.5 | 1000×870×990 |

| PE-250×400 | 250×400 | 210 | 5-21 | 6P 15 | 2.8 | 1300×1090×1270 |

| PE-400×600 | 400×600 | 340 | 16-64 | 6P 30 | 7 | 1730×1730×1630 |

| PE-500×750 | 500×750 | 425 | 40-110 | 6P 55 | 12 | 1980×2080×1870 |

| PE-600×750 | 600×750 | 500 | 80-240 | 6P 55 | 15.8 | 2070×2000×1920 |

| PE-600×900 | 600×900 | 500 | 50-160 | 6P 55 | 17 | 2190×2206×2300 |

| PE-750×1060 | 750×1060 | 630 | 110-320 | 8P 110 | 29 | 2660×2430×2800 |

| PE-800×1060 | 800×1060 | 640 | 130-330 | 8P 110 | 29.8 | 2710×2430×2800 |

| PE-830×1060 | 830×1060 | 650 | 150-336 | 8P 110 | 30.7 | 2740×2430×2800 |

| PE-870×1060 | 870×1060 | 660 | 190-336 | 8P 110 | 31.5 | 2810×2430×2800 |

| PE-900×1060 | 900×1060 | 685 | 230-390 | 8P 110 | 33 | 2870×2420×2940 |

| PE-900×1200 | 900×1200 | 750 | 220-380 | 8P 110 | 52 | 3380×2870×3330 |

| PE-1000×1200 | 1000×1200 | 850 | 315-500 | 8P 110 | 55 | 3480×2876×3330 |

| PE-1200×1500 | 1200×1500 | 1020 | 400-800 | 6P 160-220 | 100.9 | 4200×3300×3500 |

| PE-1500×1800 | 1500×1800 | 1200 | 500-1000 | 8P 280-355 | 139 | 5160×3660×4248 |

| PEX-150×750 | 150×750 | 120 | 8-25 | 4P 15 | 3.8 | 1200×1530×1060 |

| PEX-250×750 | 250×750 | 210 | 13-35 | 6P 22 | 5.5 | 1380×1750×1540 |

| PEX-250×1000 | 250×1000 | 210 | 16-52 | 6P 30 | 7 | 1560×1950×1390 |

| PEX-250×1200 | 250×1200 | 210 | 20-61 | 6P 37 | 9.7 | 2140×1660×1500 |

| PEX-300×1300 | 300×1300 | 250 | 16-105 | 6P 55 | 15.6 | 2720×1950×1600 |

Relate Products

Relate Products

Others Products

Others Products

The c160 jaw crusher greatly improves the crushing efficiency and crushing quality of the processing plant, bringing considerable benefits to customers. What is the price new model of c160 jaw crusher in my country? What is the effect? The CFTC is briefly

Jaw crusher is the most basic crushing equipment of the mine crushing production line. It roughly crushes the raw stone from the quarry. It is the first key to crush the stone into the production line.

PE jaw crusher is the main equipment in the coarse crushing stage of industrial gravel process. It is mainly composed of moving jaws, fixed jaws, spindles, connecting rods, body parts, etc., in order to assist customers to better use this equipment. The f