Max Feeding:

0-3mmCapacity:

10-280t/h.Application:Iron ore, hematite, pyrrhotite, limonite, copper ore, etc.

Application range:Widely used in metallurgy, mining, chemical, cement, construction, refractory materials and ceramics industries.

Email: jacker@cfcmining.com

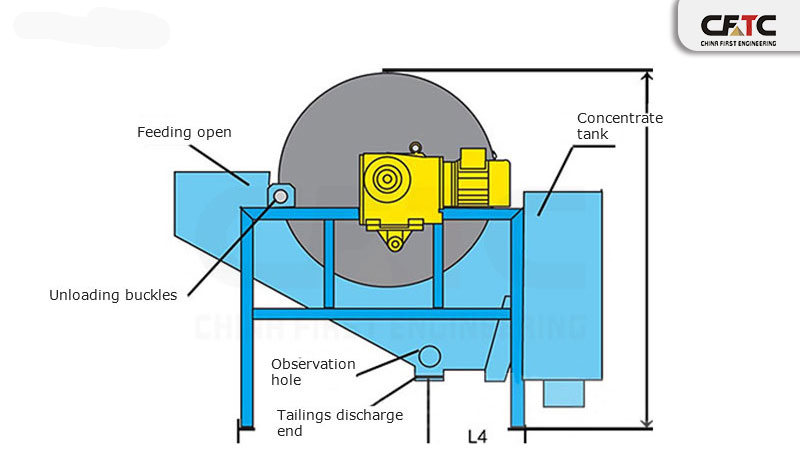

The magnetic separator is suitable for iron ore beneficiation of magnetite, pyrrhotite, roasting ore and ilmenite with a diameter larger than 3mm. It is also suitable for coal, non-metallic minerals, building materials and other iron removal work.

The material is fed from the left hollow journal to the cylinder, and then enters the cylindrical magnetic separator, and gradually spreads to the right. When the material moves from left to right, the cylinder of the cylindrical magnetic separator will The steel ball is brought to a certain height and falls to crush the material, and a part of the steel ball has a grinding effect on the material when the cylinder is discharged, and the whole moving process is also a crushing process of the material. The broken material is discharged from the hollow journal to complete the grinding work.

| Type | Barrel diameter(mm) | Barrel length(mm) | speed(r/min) | feed(mm) | capacity(t/h) | power(kw) |

| CTB6012 | 600 | 1200 | <35 | 2-0 | 10-20 | 1.5 |

| CTB6018 | 600 | 1800 | <35 | 2-0 | 15-30 | 2.2 |

| CTB7518 | 750 | 1800 | <35 | 2-0 | 20-45 | 2.2 |

| CTB9018 | 900 | 1800 | <35 | 3-0 | 40-60 | 3 |

| CTB9021 | 900 | 2100 | <35 | 3-0 | 45-60 | 3 |

| CTB9024 | 900 | 2400 | <28 | 3-0 | 45-70 | 4 |

| CTB1018 | 1050 | 1800 | <20 | 3-0 | 50-75 | 5.5 |

| CTB1021 | 1050 | 2100 | <20 | 3-0 | 50-100 | 5.5 |

| CTB1024 | 1050 | 2400 | <20 | 3-0 | 60-120 | 5.5 |

| CTB1218 | 1200 | 1800 | <18 | 3-0 | 80-140 | 5.5 |

| CTB1224 | 1200 | 2400 | <18 | 3-0 | 85-180 | 7.5 |

| CTB1230 | 1200 | 3000 | <18 | 3-0 | 100-180 | 7.5 |

| CTB1530 | 1500 | 3000 | <14 | 3-0 | 170-280 | 11 |

Relate Products

Relate Products

Others Products

Others Products