Max Feeding:

0-1280mmCapacity:

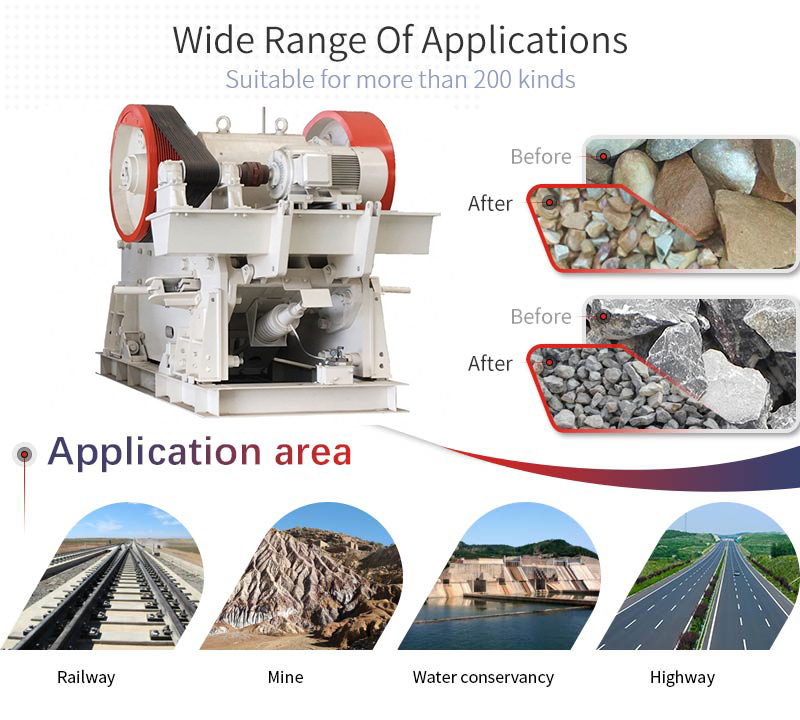

160-1510TPHApplication:Granite, marble, basalt, limestone, quartz, pebble, copper ore, iron ore

Application range:Widely used in metallurgy, mining, chemical, cement, construction, refractory materials and ceramics industries.

Email: jacker@cfcmining.com

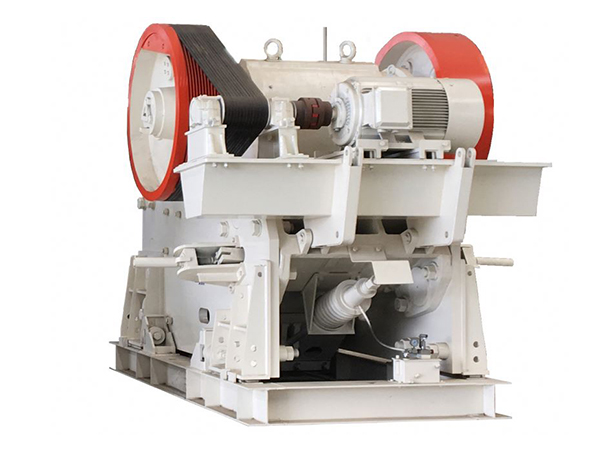

C6X Series rock jaw crusher machine price is new equipment used for crushing hard or abrasiveness stones.

C6X Jaw Crusher is new equipment used for crushing hard or abrasiveness stones. It is possess of detachable frame without welding structure, optimize the cavity structure,double wedge adjusting device, high quality raw materials and components,elasticity limit damping device, integrated motor frame etc unique design, high crushing efficiency,low investment cost, long service life,high efficiency,safety and stability,will popular in the market.

Working Principle:

Firstly, the motor drives belt and pulley to make the movable jaw move back and forth, up and down around the eccentric shaft. When the movable jaw pushes the movable jaw plate towards the fixed jaw plate, materials get crushed. When movable jaw and plate move backwards under the action of the eccentric shaft and spring, the materials crushed before would be discharged from the port under the jaw plate. As the motor works continuously, the movable jaw can crush or discharge materials periodically, so that volume production can be achieved.

| Model | Feed opening (mm) | Maximum feeding size (mm) | Range of discharge opening (mm) | Capacity(t/h) | Speed(r/min) | Power(kw) | Overall dimension (mm) |

| C6X80 | 520×800 | 420 | 60-150 | 80-290 | 350 | 75 | 2650×1540×1780 |

| C6X100 | 760×1000 | 630 | 70-175 | 130-420 | 260 | 110 | 3700×2440×2520 |

| C6X110 | 850×1100 | 720 | 80-200 | 160-550 | 230 | 160 | 3800×2450×2550 |

| C6X125 | 950×1250 | 800 | 125-250 | 280-760 | 220 | 160 | 4100×2750×2780 |

| C6X145 | 1100×1450 | 920 | 150-275 | 370-950 | 220 | 200 | 4400×3060×3210 |

| C6X160 | 1200×1600 | 1020 | 175-300 | 470-1100 | 220 | 250 | 5700×3650×3550 |

| C6X200 | 1500×2000 | 1200 | 200-300 | 620-1500 | 200 | 400 | 6500×3990×4260 |

Relate Products

Relate Products

Others Products

Others Products

The jaw plate is the most important accessory in the jaw crusher and the most vulnerable part, so it often needs to be replaced.

PE jaw crusher is the main equipment in the coarse crushing stage of industrial gravel process. It is mainly composed of moving jaws, fixed jaws, spindles, connecting rods, body parts, etc., in order to assist customers to better use this equipment. The f

The Mobile Jaw Crusher Station adopts a flexible walking mode, integrating mechanical, hydraulic, electrical, and intelligent control technologies, eliminating