Max Feeding:

<500mmCapacity:

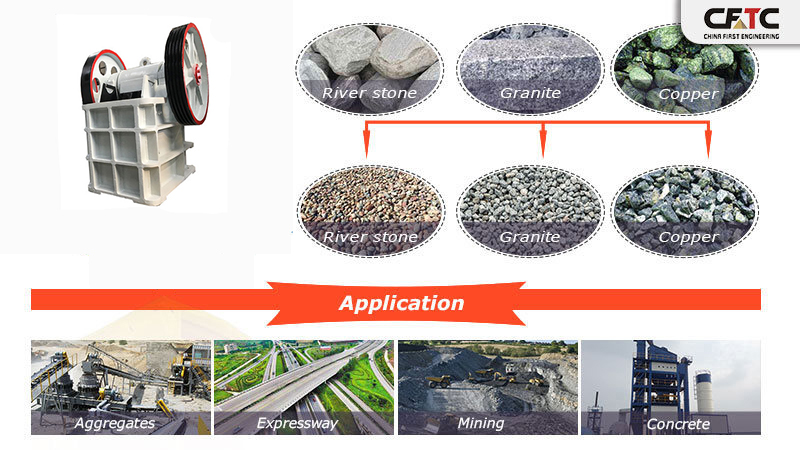

50-160 tphApplication:granite, marble, basalt, limestone, quartz, cobble, iron ore, copper ore, and some other mineral & rocks.

Application range:Widely used in metallurgy, mining, chemical, cement, construction, refractory materials and ceramics industries.

Email: jacker@cfcmining.com

Jaw crusher pe 600 x 900 have big broken ratio, product size is even, simple structure, reliable operation, maintenance is simple and convenient, cost is economic and so on characteristic, it is applicabe for crushing various materials with compression re

Jaw crusher pe 600 x 900 is mainly used for medium-size crushing of various ores and bulk materials, and is widely used in mining, smelting, building materials, roads, railways, water conservancy and chemical industries. The highest compressive strength of the material to be crushed is 320 MPa. The performance characteristics are large crushing ratio, uniform product granularity, simple structure, reliable performance, simple maintenance and low operating cost.

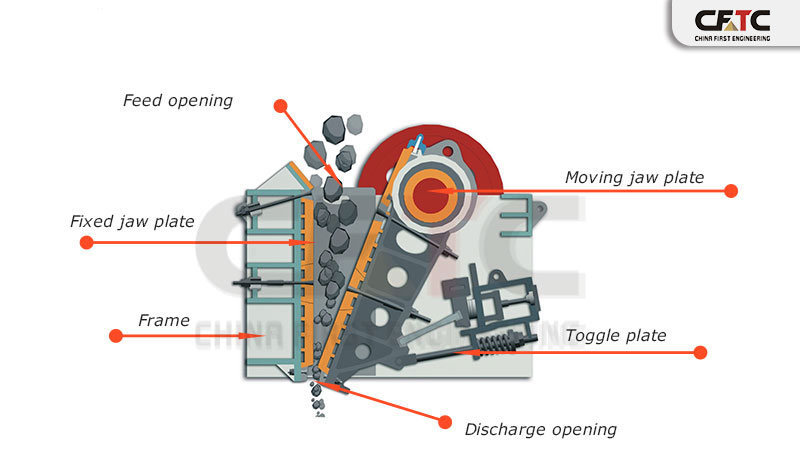

When Jaw crusher working, motor through the pulley drive the eccentric shaft rotation, from the period of hubei near, fixed jaw, and for the material such as extrusion, rolling and run multiple broken, make material from large to small, gradually whereabouts until discharge through the discharge port.

| Type | Feed port size (mm) |

Max Feeding (mm) |

Capacity (t/h) |

Power (kw) |

Weight (t) |

Shape(mm) |

| PE-150×250 | 150×250 | 125 | 1-3 | 4P 5.5 | 0.8 | 720×660×850 |

| PE-200×300 | 200×300 | 180 | 2-6 | 4P 7.5 | 1.2 | 910×750×990 |

| PE-200×350 | 200×350 | 180 | 3-10 | 4P 11 | 1.5 | 1000×870×990 |

| PE-250×400 | 250×400 | 210 | 5-21 | 6P 15 | 2.8 | 1300×1090×1270 |

| PE-400×600 | 400×600 | 340 | 16-64 | 6P 30 | 7 | 1730×1730×1630 |

| PE-500×750 | 500×750 | 425 | 40-110 | 6P 55 | 12 | 1980×2080×1870 |

| PE-600×750 | 600×750 | 500 | 80-240 | 6P 55 | 15.8 | 2070×2000×1920 |

| PE-600×900 | 600×900 | 500 | 50-160 | 6P 55 | 17 | 2190×2206×2300 |

| PE-750×1060 | 750×1060 | 630 | 110-320 | 8P 110 | 29 | 2660×2430×2800 |

| PE-800×1060 | 800×1060 | 640 | 130-330 | 8P 110 | 29.8 | 2710×2430×2800 |

| PE-830×1060 | 830×1060 | 650 | 150-336 | 8P 110 | 30.7 | 2740×2430×2800 |

| PE-870×1060 | 870×1060 | 660 | 190-336 | 8P 110 | 31.5 | 2810×2430×2800 |

| PE-900×1060 | 900×1060 | 685 | 230-390 | 8P 110 | 33 | 2870×2420×2940 |

| PE-900×1200 | 900×1200 | 750 | 220-380 | 8P 110 | 52 | 3380×2870×3330 |

| PE-1000×1200 | 1000×1200 | 850 | 315-500 | 8P 110 | 55 | 3480×2876×3330 |

| PE-1200×1500 | 1200×1500 | 1020 | 400-800 | 6P 160-220 | 100.9 | 4200×3300×3500 |

| PE-1500×1800 | 1500×1800 | 1200 | 500-1000 | 8P 280-355 | 139 | 5160×3660×4248 |

| PEX-150×750 | 150×750 | 120 | 8-25 | 4P 15 | 3.8 | 1200×1530×1060 |

| PEX-250×750 | 250×750 | 210 | 13-35 | 6P 22 | 5.5 | 1380×1750×1540 |

| PEX-250×1000 | 250×1000 | 210 | 16-52 | 6P 30 | 7 | 1560×1950×1390 |

| PEX-250×1200 | 250×1200 | 210 | 20-61 | 6P 37 | 9.7 | 2140×1660×1500 |

| PEX-300×1300 | 300×1300 | 250 | 16-105 | 6P 55 | 15.6 | 2720×1950×1600 |

Relate Products

Relate Products

Others Products

Others Products

PE jaw crusher is the main equipment in the coarse crushing stage of industrial gravel process. It is mainly composed of moving jaws, fixed jaws, spindles, connecting rods, body parts, etc., in order to assist customers to better use this equipment. The f

Jaw crusher is different in terms of model size, output, quality, etc. Currently, there are more and more manufacturers of jaw crushers, so many customers do not know how to choose the most suitable crushing equipment.

The role of different parts together ensures the safe production process of the equipment. The lining board is one of the machine parts. Here is the role of the lining board.