Details:

Kashmir, India, has abundant local mining resources. Considering the current demand for aggregate materials in the market, customers have decided to invest in the production of fine sandstone aggregates to achieve enterprise transformation.

Project Overview:

Raw material: granite

Capacity: 200 TPH

Finished product: concrete aggregate

Finished product specifications: 0-5mm (mechanical sand), 5-10-20mm

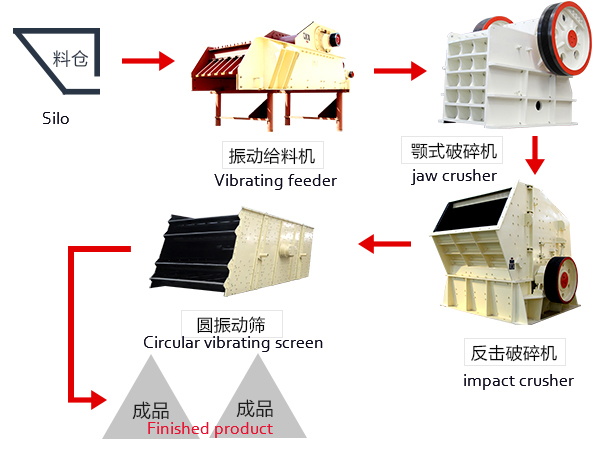

Equipment: F5X feeder, C6X jaw crusher, HST315 single cylinder hydraulic breaker, VSI6X1150 sand making machine, S5X vibrating screen

In the multi-party inspection and comparative analysis of customers, in the end, CFTC won the favor of customers with excellent equipment, perfect process plan and good industry reputation.

Currently, the project has been officially put into production. From the analysis of the operation, the two mobile crushing stations provided by CFTC are very stable, the production capacity is up to standard, and the quality of the finished materials is high. The customers are very satisfied with this. In addition, the project achieved high production efficiency at a lower production cost and attracted many visitors from around the city.

Project Benefits:

Advanced technology and reliable equipment

Adopting domestic advanced technology, mature technology and reliable performance equipment, the overall production technology and process equipment are at the domestic advanced level. The core equipment and solutions are designed and provided by the professional team of Shibang Group. The equipment quality is reliable and the process flow is smooth.

High quality aggregate with high added value

The proportion of finished materials can be flexibly adjusted according to market conditions, and the quality of finished products is excellent. In the market environment where aggregate prices are soaring, the production line is put into production, which not only meets customers' high standards for aggregates, but also brings considerable return on investment to customers.

Green

The line is produced by wet process. The belt conveyor is equipped with a dust cover to prevent dust. At the same time, the production line is equipped with a sewage treatment system, and the sewage in the production process can be recycled after the treatment, and the sewage is discharged.

Convenient transportation

The project site has convenient transportation and is close to Chizhou High-speed Railway Station. The production line is only 3 kilometers away from Tongluo Pier. The waterway transportation is convenient, the output of finished products is convenient, and the transportation cost is low.

Relate Products

Relate Products

Others Products

Others Products

huayikevin@gmail.com

huayikevin@gmail.com

prices?

prices?

How to ship?

How to ship?

service?

service?

Spare parts?

Spare parts?