Max Feeding:

5.5-45(kW).Capacity:

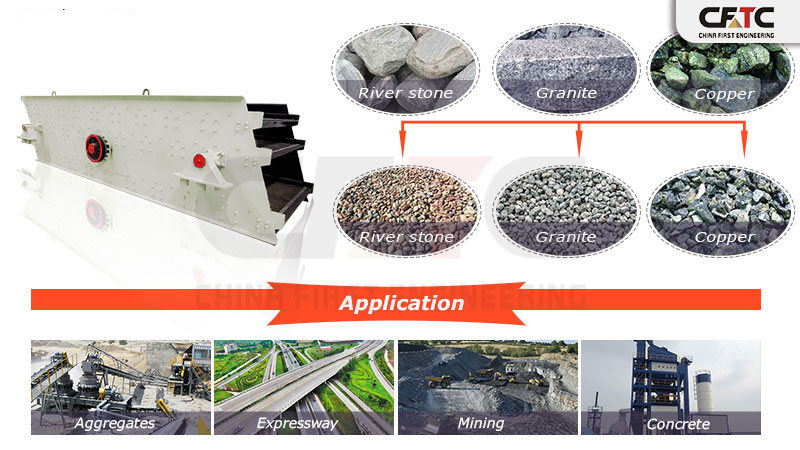

20-850m³/h.Application:

Application range:Widely used in metallurgy, mining, chemical, cement, construction, refractory materials and ceramics industries.

Email: jacker@cfcmining.com

Circular Vibrating Screen is mainly composed by screen case, screen mesh, vibrator, anti-vibrating spring and machine base. The vibrator is set on the side board of the vibrating box. It is motivated to whirl by the electric motor’s driving for the coupl

The Circular Vibrating Screen machine is a kind of common screening machine, widely used in crushing, and sand making, and mineral processing. The vibrating screen is a multi-layer, high-efficiency new vibrating screen, also known as a sorting screen or a screening machine.

Circular vibrating screen uses the motor driving two pairs of exciters on the both sides of screen box through the couplings with rubber type element. The two pairs of exciters, connecting with the universal joint coupling in the middle, rotate synchronously under the unequal centrifugal force. Under the action of the exciters and the spring group, the screen box can be vibrated in full amplitude by the near circular track. Meanwhile, the raw materials on the screens are thrown under the action of the screen box vibrating. During the process of raw materials jumping and rolling forward, the materials smaller than the sieve mesh will fall down layer by layer until out of the screen box.

Model |

Sieve |

Sieve obliquity(°) | Screen area(m²) | Vibrate frequency(r/min) | Double amplitude |

Capacity (m³/h) |

Power(kW) | Transport size(L×W×H)(mm) |

| YK1235 | 1 | 15 | 4.2 | 970 | 6.0-8.0 | 20-180 | 5.5 | 3790x1847x1010 |

| 2YK1235 | 2 | 5.5 | 4299×1868×1290 | |||||

| 3YK1235 | 3 | 7.5 | 4393×1868×1640 | |||||

| 4YK1235 | 4 | 11 | 4500×1967×2040 | |||||

| YK1545 | 1 | 17.5 | 6.75 | 970 | 6.0-8.0 | 25-240 | 11 | 5030×2200×1278 |

| 2YK1545 | 2 | 11 | 5767×2270×1550 | |||||

| 3YK1545 | 3 | 11 | 5874×2270×1885 | |||||

| 4YK1545 | 4 | 18.5 | 5994×2270×2220 | |||||

| YK1548 | 1 | 17.5 | 7.2 | 970 | 6.0-8.0 | 28-270 | 15 | 5330×2228×1278 |

| 2YK1548 | 2 | 15 | 5174×2270×1885 | |||||

| 3YK1548 | 3 | 15 | 6067×2270×1557 | |||||

| 4YK1548 | 4 | 18.5 | 6294×2270×2220 | |||||

| YK1860 | 1 | 20 | 10.8 | 970 | 6.0-8.0 | 32-350 | 15 | 6536×2560×1478 |

| 2YK1860 | 2 | 18.5 | 6826×2570×1510 | |||||

| 3YK1860 | 3 | 18.5 | 7145×2570×1910 | |||||

| 4YK1860 | 4 | 22 | 7246×2660×2244 | |||||

| YK2160 | 1 | 20 | 12.6 | 970 | 6.0-8.0 | 40-720 | 18.5 | 6535×2860×1468 |

| 2YK2160 | 2 | 22 | 6700×2870×1560 | |||||

| 3YK2160 | 3 | 20 | 7146×2960×1960 | |||||

| 4YK2160 | 4 | 30 | 7254×2960×2205 | |||||

| YK2460 | 1 | 20 | 14.4 | 970 | 6.0-8.0 | 50-750 | 18.5 | 6535×3210×1468 |

| 2YK2460 | 2 | 970 | 30 | 7058×3310×1760 | ||||

| 3YK2460 | 3 | 840 | 30 | 7223×3353×2220 | ||||

| 4YK2460 | 4 | 840 | 30 | 7343×3893×2445 | ||||

| YK2475 | 1 | 20 | 18 | 970 | 6.0-8.0 | 60-850 | 20 | 7995×3300×1552 |

| 2YK2475 | 2 | 840 | 30 | 8863×3353×1804 | ||||

| 3YK2475 | 3 | 840 | 37 | 8854×3353×2220 | ||||

| 4YK2475 | 4 | 840 | 45 | 8878×3384×2520 |

Relate Products

Relate Products

Others Products

Others Products