Max Feeding:

<800mmCapacity:

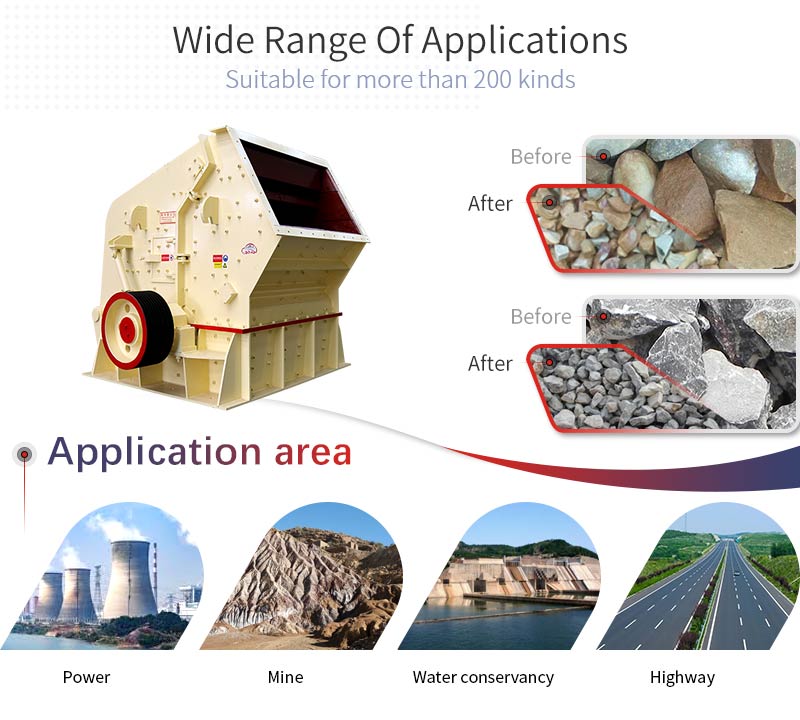

30-800 t/hApplication:ore crushing, railways, highways, energy, cement, chemicals, construction and other industries.

Application range:Widely used in metallurgy, mining, chemical, cement, construction, refractory materials and ceramics industries.

Email: jacker@cfcmining.com

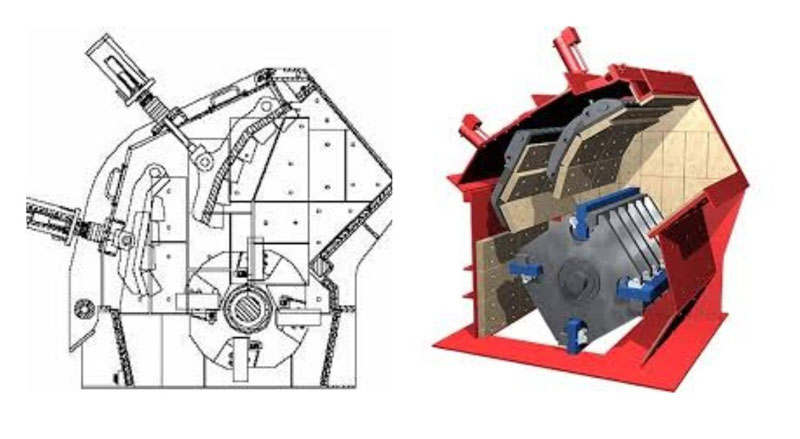

HSI Impact Crusher with the advanced world standard is latest generation product, absorbing the latest technology around the world. Because the rotor is the key part of the impact crusher and also the most critical part of inspection and acceptance

our company develop and produce the strong and heavy type rotor in order to get the higher rotary inertia. The use of high abrasion-resistant material and the best design of the crushing chamber make the performance of the crusher more remarkable.

Featuring a 4 rows of blow bars balanced rotor assembly, these machines offer smooth operation. When the impact crusher works, the motor drives the rotor rotating at a high speed, on which the blow bars installed. When the materials goes into the area where the blow bars takes the impacting force, under their impact function at a high speed, the materials are thrown to the impact device above the rotor continuously. And then the materials are rebounded from the impact liner to the area where the blow bar works for being crushed again. The materials from large to small all to be crushed in the impact chamber repeatedly. The process won't stop until the materials are crushed to the required size and then discharged from outlet .

| Model | Specification (mm) |

Feed opening (mm) |

The Maximum Feeding Size (mm) |

Capacity (t/h) |

Power (kw) |

Overall dimension (L×W×H) (mm) |

Total weight (t) |

| PF-1007 | Φ1000×700 | 400×730 | 300 | 30-70 | 4P 37-45 | 2330×1660×2300 | 12 |

| PF-1010 | Φ1000×1050 | 400×1080 | 350 | 50-90 | 4P 45-55 | 2370×1700×2390 | 15 |

| PF-1210 | Φ1250×1050 | 400×1080 | 350 | 70-130 | 6P 110 | 2680×2160×2800 | 17.7 |

| PF-1214 | Φ1250×1400 | 400×1430 | 350 | 80-180 | 6P 132 | 2650×2460×2800 | 22.4 |

| PF-1315 | Φ1320×1500 | 860×1520 | 500 | 100-280 | 6P 200 | 3180×2720×3120 | 27 |

| PF-1320 | Φ1300×2000 | 993×2000 | 500 | 140-380 | 6P 250 | 3220×3100×3120 | 34 |

| PF-1520 | Φ1500×2000 | 830×2040 | 700 | 200-550 | 4P 315-400 | 3959×3564×3330 | 50.6 |

| PF-1820 | Φ1800×2000 | 1260×2040 | 800 | 400-800 | 4P 630-710 | 4400×3866×4009 | 83.21 |

Relate Products

Relate Products

Others Products

Others Products