Max Feeding:

<300mmCapacity:

12-2200t/hApplication:metallurgical industry, building materials industry, road construction industry, chemical industry and silicate industry.

Application range:Widely used in metallurgy, mining, chemical, cement, construction, refractory materials and ceramics industries.

Email: jacker@cfcmining.com

The cone crusher is suitable for the crushing of raw materials in the metallurgy, construction, road construction, chemical and silicate industries, and can break various ores and rocks of medium and medium hardness.

Compared with other crushing machines, cone crusher crushing has the advantages of high crushing efficiency, low energy consumption and uniform product size.

There are 4 different types of cone crushers, including the single-cylinder cone crusher, multi-cylinder hydraulic cone crusher, hydraulic cone crusher, compound cone crusher, also named Symons cone crusher.

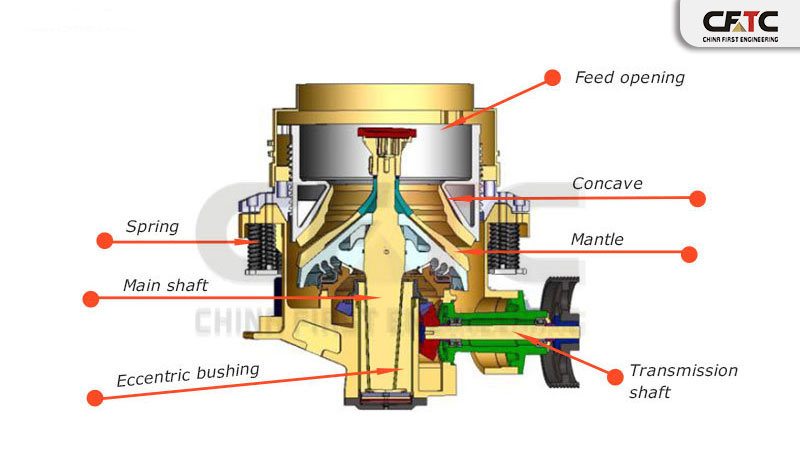

Cone crusher working principle:

During operation, the rotation of the motor is rotated by a pulley or a linkage shaft, a cone crusher drive shaft and a conical crusher cone under a urging of the eccentric sleeve. Therefore, the crushing crucible of the crushing cone is close to the surface of the corrugated wall fixed on the adjusting sleeve, so that the ore is continuously subjected to impact, pressing and bending in the crushing chamber to realize the crushing of the ore.

| Specification | Model | Diameter of large end of crushing cone (mm) |

Max.feeding size(mm) |

Width of discharge opening (mm) |

Processing capacity (t/h) |

Motor power (kw) |

Total weight (t) |

Dimensions (L×W×H) (mm) |

| Φ600 | PYB600 | 600 | 65 | 12-25 | 40 | 8P 30 | 5 | 2234×1370×1675 |

| PYD600 | 35 | 3-13 | 12-23 | 5.5 | 2234×1370×1675 | |||

| Φ900 | PYB900 | 900 | 115 | 15-50 | 50-90 | 8P 55 | 11.2 | 2692×1640×2350 |

| PYZ900 | 60 | 5-20 | 20-65 | 11.2 | 2692×1640×2350 | |||

| PYD900 | 50 | 3-13 | 15-50 | 11.3 | 2692×1640×2350 | |||

| Φ1200 | PYB1200 | 1200 | 145 | 20-50 | 110-168 | 8P 110 | 24.7 | 2790×1878×2844 |

| PYZ1200 | 100 | 8-25 | 42-135 | 25 | 2790×1878×2844 | |||

| PYD1200 | 50 | 3-15 | 18-105 | 25.3 | 2790×1878×2844 | |||

| Φ1750 | PYB1750 | 1750 | 215 | 25-50 | 180-360 | 8P 160 | 50.3 | 3910×2894×3809 |

| PYZ1750 | 185 | 10-30 | 80-210 | 50.3 | 3910×2894×3809 | |||

| PYD1750 | 85 | 5-13 | 60-180 | 50.2 | 3910×2894×3809 | |||

| Φ2200 | PYB2200 | 2200 | 300 | 30-60 | 420-700 | 8P 280-260 | 80 | 4622×3302×4470 |

| PYZ2200 | 230 | 10-30 | 130-410 | 80 | 4622×3302×4470 | |||

| PYD2200 | 100 | 5-15 | 80-200 | 81.4 | 4622×3302×4470 |

Relate Products

Relate Products

Others Products

Others Products

The jaw crusher and the cone crusher are both crushed materials. Why are the prices different? What's the difference?

Cone crusher has become a wide range of crushing equipment. Its crushing ratio is large, its efficiency is high, its energy consumption is low, and its uniform particle size makes it suitable for crushing hard or medium-hard ore..