Max Feeding:

1-50Capacity:

1-120tphApplication:Fluorite Ore,Barite Ore,Garnet ore,Celestite Ore,Copper ore, Tin ore, Lead ore, Iron ore, Manganese Ore, Chromite ore, Ferrochrome Slag,SilicoManganese Slag,Copper slag, etc.

Application range:Widely used in metallurgy, mining, chemical, cement, construction, refractory materials and ceramics industries.

Email: jacker@cfcmining.com

LTA jig machine widely used in the gravity dressing of metals such as tungsten, tin, gold, red iron, brown iron, manganese, titanium, antimony, lead, antimony and antimony.

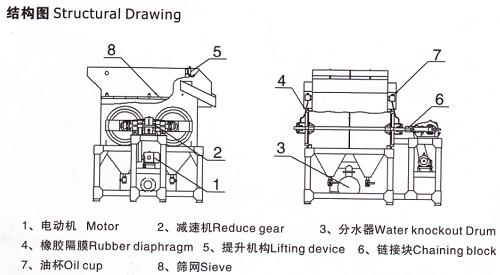

1. The LTA jig machine is a single-row double-chamber lower-moving jig, also known as a lower-moving conical diaphragm jig. The machine uses water as a medium and sorts according to the difference in specific gravity (density) between minerals and gangue. The principle of mineral separation is based on gravity beneficiation theory. The jigging waveform of the normal operation of the LTA1010 jig is sinusoidal and has the characteristics of uniform rising water flow. The series of jigs have the advantages of large processing capacity, high recovery rate and continuous work.

LTA series jiggers are the down-moving tri-rooms jigger. It transmits by the pulley of the eccentric shaft driven by the motor.The eccentric shaft bear form decentraction motion after the adjustment of the adjustment device and the connection rod will be driven to do the alternating movement. The other end of the connecting rod is fixed on the moving shaft of the moving frame. There is a supporting point connecting to the rack section in the center of the moving frame, so the moving frame will be driven to do the up-down alternating motion focusing on the supporting point. The down-centrum fixed on the moving frame move up-down alternatively passively to press the water flow in the case to product waves and the waving water flow through the screen will dash the bed medium and the ore to do parabola motion. The ore will be fed at the feeding port, and the ore will drop in different speed to separate naturally. The ore with small density will be discharged out of the machine as a result of the water flow while the ore with big density will go through the bed medium to enter the down-centrum and will be discharged from the concentrate discharging port to finish the jigging beneficiation.

Relate Products

Relate Products

Others Products

Others Products