Max Feeding:

0.15-2mm.Capacity:

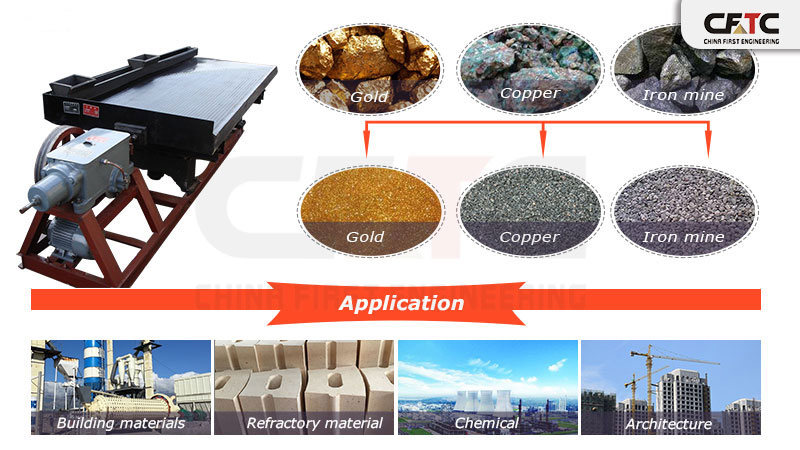

10-60t/d.Application:Used in the selection of tin, tungsten, gold and silver, lead, zinc, antimony, antimony, iron, manganese, ferrotitanium and coal.

Application range:Widely used in metallurgy, mining, chemical, cement, construction, refractory materials and ceramics industries.

Email: jacker@cfcmining.com

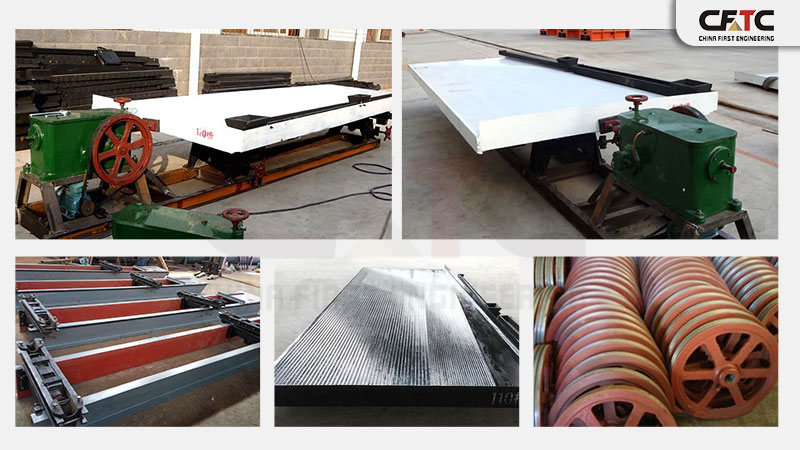

The Concentrating Table is a gravity beneficiation equipment for sorting fine-grained materials.

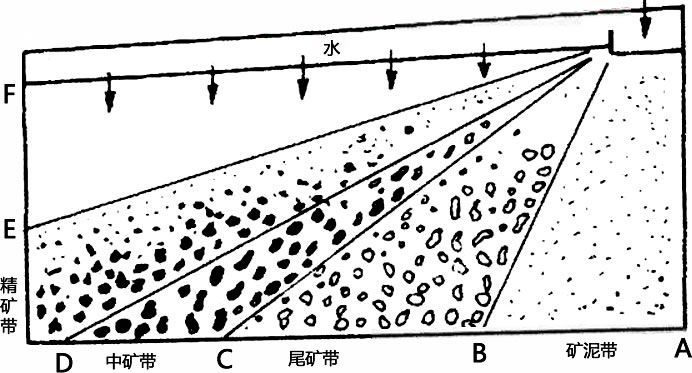

Concentrating Table beneficiation is a combination of mechanical slab symmetric reciprocating motion and thin layer bevel water flow on a sloping bed surface to loosely layer and divide the ore particles on the bed surface, so that the minerals are sorted according to the density.

| Type | Feeding granularity(mm) | Capacity(t/d) |

power | weight (t) |

shape (mm) |

| 9YC suspension three-layer concentrating Table | 0.04-0.5 | 9.6-2.8 | 1.5 | 2.14 | 5725×2020×2950 |

| 6-S suspension three-layer concentrating Table | 0.02-2 | 15-105 | 1.1 | 0.85 | 5600×1825×1560 |

| LY suspension three-layer concentrating Table | 0.02-2 | 15-105 | 1.1 | 1.25 | 5600×1825×1560 |

| XZY2100×1050 small concentrating Table | 0-4 | 7.2-19.2 | 1.1 | 0.694 | 3090×1050×1033 |

Relate Products

Relate Products

Others Products

Others Products